ULTRA.PLUS System

THE BEST

WE'VE EVER BUILT!

In agricultural operations, the transmission of power via drive shafts is still one of the most important and efficient drive concepts. As early as the 1950s Walterscheid was producing its first agricultural PTO drive shaft and within a very short time it had made its name as a specialist supplier worldwide with its innovative developments.

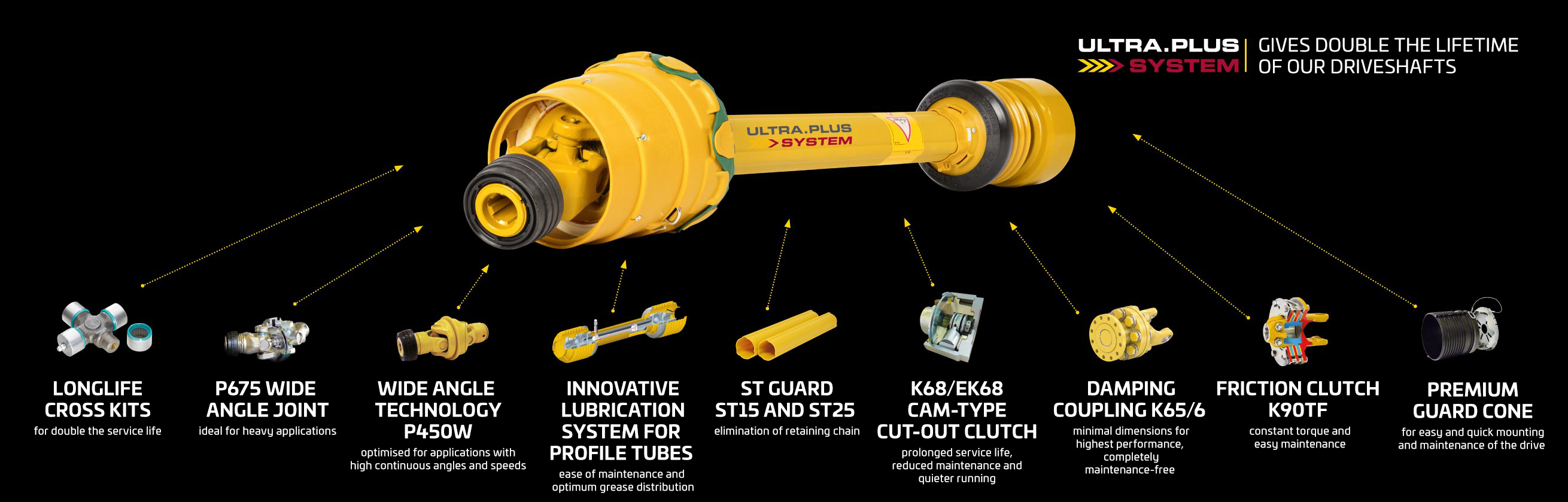

Around 65 years later the engineers of Walterscheid took the “yellow PTO drive shaft” through a thorough further development. The result is the new ULTRA.PLUS system which can be employed in nearly all series of PTO drive shafts from Walterscheid.

The new PTO drive shafts with the ULTRA.PLUS system achieve a previously unattainable level of performance, functionality and ease of maintenance. For this purpose all the major functional areas and components of the PTO drive shaft have been completely re-engineered.

ULTRA.Longlife • Long-life Cross kits • Central lubrication for profile tubes • Zero maintenance P450 wide angle joint • Cam-type cut-out clutch K68

ULTRA.Safety • New guard concept • New implement-side guard cone • Profiled ST guard • Full guard for wide angle joints • Elimination of retaining chains

ULTRA.Easy • Simple assembly • Excellent accessibility • Integrated lubrication system with only one lubricating grease nipple • Easy-to-service profile tube

ULTRA.Efficient • The world's strongest wide angle joint for the heaviest-duty applicatons • Long-life cross for double the service life and extended maintenance interval

New standards in the functionality  and service life of PTO drive shafts – with the Walterscheid ULTRA.PLUS system

and service life of PTO drive shafts – with the Walterscheid ULTRA.PLUS system

With the ULTRA.PLUS system Walterscheid redefines the functionality and service life of drive shafts. The individual components, all of which were optimized for maximum functionality, add up to be the best Walterscheid drive shaft ever: the highest efficiency, longest service life and unbeatable user-friendliness.

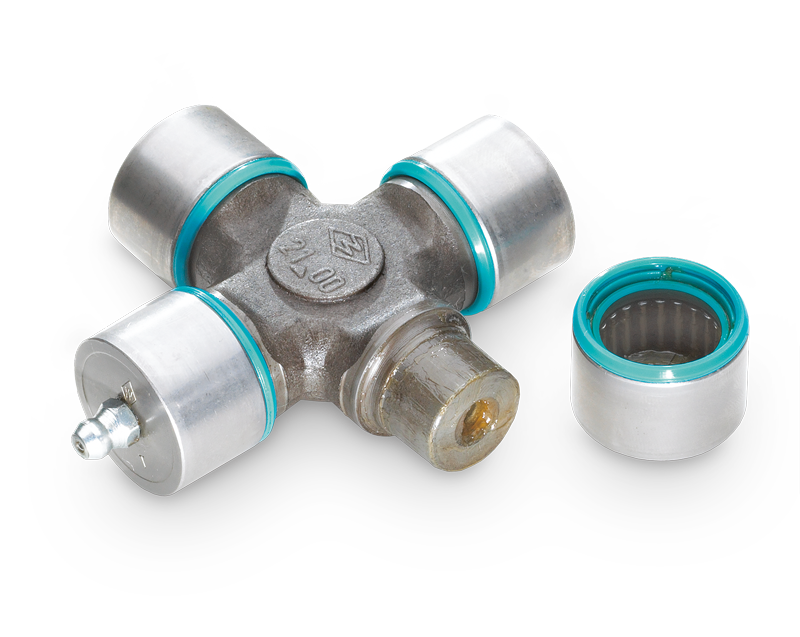

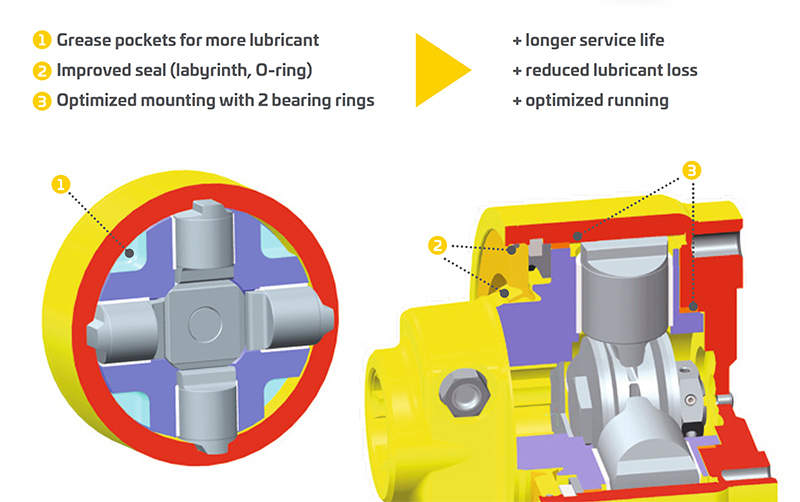

LONG-LIFE CROSS KIT – for double the service life

The new universal joint at a glance:

The new universal joint at a glance:

- New lubricant

- New manufacturing process

- Multi-lip seal

- Grease-nipple-in-cap lubrication

The new universal joints are one example of technological enhancements which will be applied in future Walterscheid drive shafts. With these universal joints the combination of the proven turquoise multi-lip seal, precision manufacturing and innovative lubricants ensure substantially improved performance.

The ULTRA.PLUS system now offers a doubling of the joint’s service life, and a clear increase in operating reliability, whilst maintenance efforts and wear are considerably reduced. The environmental friendliness of the new universal joints is also improved through better grease retention, something which is of increasing relevance. Finally, greasing has also become significantly easier, thanks to the proven grease-nipple-in-cap lubrication technology.

The new universal joint is available in the sizes 2400, 2500 and 2600.

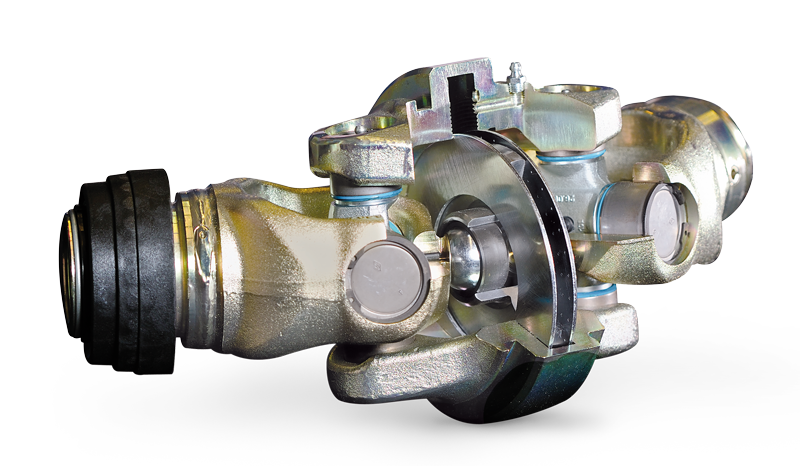

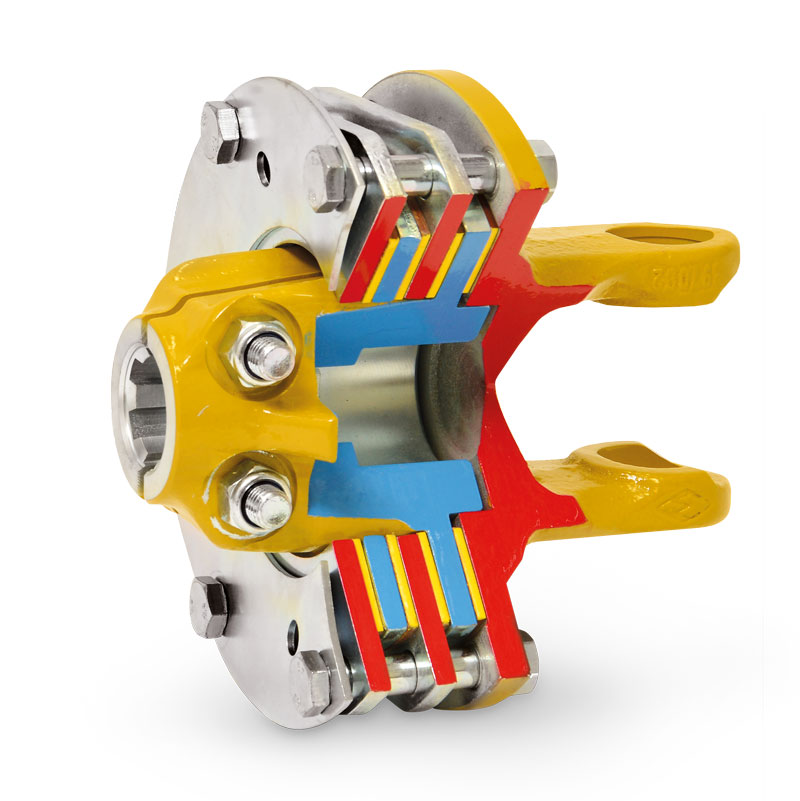

P675 – ideal for heavy-duty applications

The P675 wide-angle joint at a glance:

- For heavy-duty applications and tractor power ratings up to 400 hp

- Encased design

- Longer lifetime

- Easily accessible lubrication grease nipple

- 60-hour maintenance interval

- Smooth running

The P675 wide angle joint supplements the ULTRA.PLUS System for applications with the highest performance requirements. Key to the joint is its ability to reach a maximum angle for short periods of 75°, and in continuous operation the P675 is designed for a maximum articulation angle of 25°.

This joint was developed specifically for demanding applications, such as loader wagons, big bale presses, for tillage, or for driving diggers. It is designed for a maximum tractor power of up to 400hp. The P675’s impressive features include not only the 60-hour maintenance interval, but also its long service life and smooth running characteristics.

The P675 Power Drive wide angle joint has the familiar product features of the Walterscheid Power Drive series, for example dirt-repellent multi-lip seals and sturdy needle roller bearing technology. The completely encased design protects the joint from environmental influences and prevents the ingress of dust or harvest product residues.

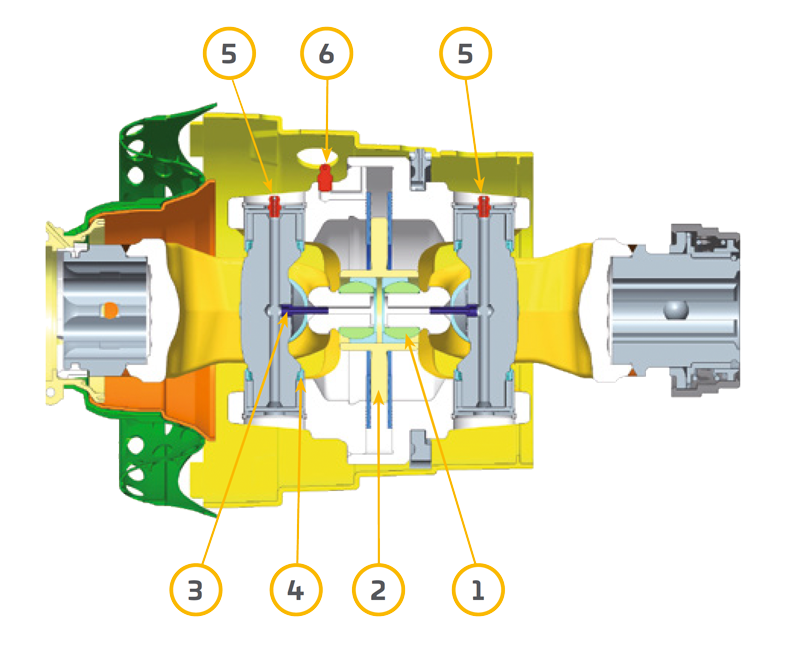

High quality pivot bearings (1) reduce the wear on the guidance system. Floating discs with lubricant chambers (2) lubricant from escaping and dirt particles from entering when an opening is created as the joint is put at an angle. This increases the lifetime of the guidance system.

High quality pivot bearings (1) reduce the wear on the guidance system. Floating discs with lubricant chambers (2) lubricant from escaping and dirt particles from entering when an opening is created as the joint is put at an angle. This increases the lifetime of the guidance system.

The central lubrication system (3) the joint adequately with lubricant. The joint crosses are fitted with the blue “P” seal (4). The cap bottom lubrication (5) and the double-fork direct lubrication (6) help make the lubrication process easier.

NEW P450 WIDE-ANGLE TECHNOLOGY – optimised for applications with permanently high articulation angles and speeds

The P450 wide-angle joint at a glance:

- Maintenance-free

- Fully enclosed design

- Environmentally friendly with no loss of lubricant

- Small rotation diameter

- Smooth running characteristics

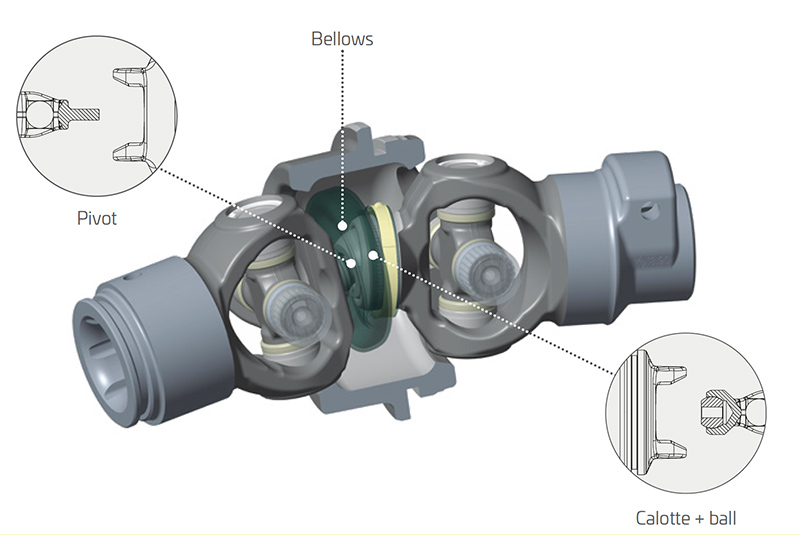

Walterscheid engineers have developed the new P450 constant velocity joint as a further component of the ULTRA.PLUS system. This compact 50° wide-angle joint is the ideal supplement to the proven 80°/75° wide angle joints. The new P450 joint can be used wherever a maximum angle of 50° is not exceeded.

The new P450 wide-angle joint is designed specifically for use with large permanent angles and, thanks to its fully enclosed design, it works in an environmentally friendly fashion without any loss of lubricant. With its innovative centring system the P450 is suitable for high speeds, provides a considerable degree of smooth running and is maintenance-free because of the completely sealed and low-wear centring system.

The combination with standard joints, wide angle joints as well as with overload and overrunning clutches allows for versatile potential applications. The new P450 wide-angle joint is available in the size W2400 / P400.

INNOVATIVE CENTRING SYSTEM & ENCASED DESIGN

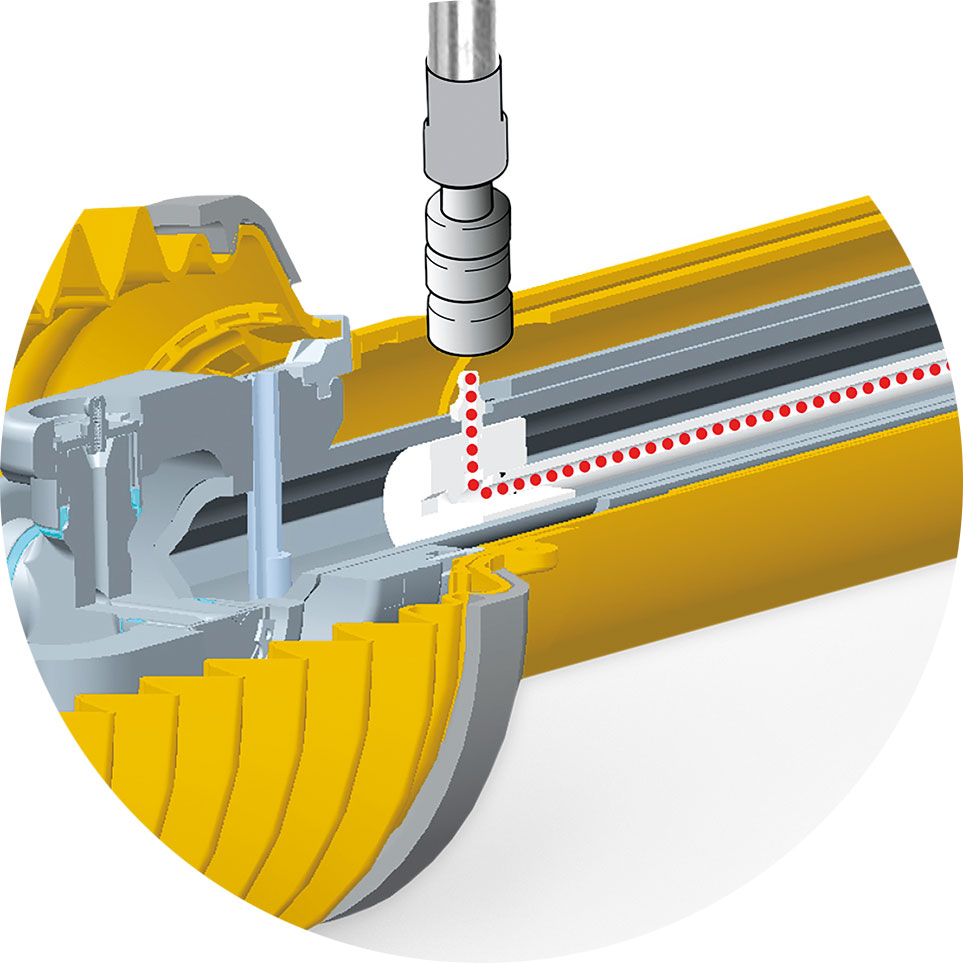

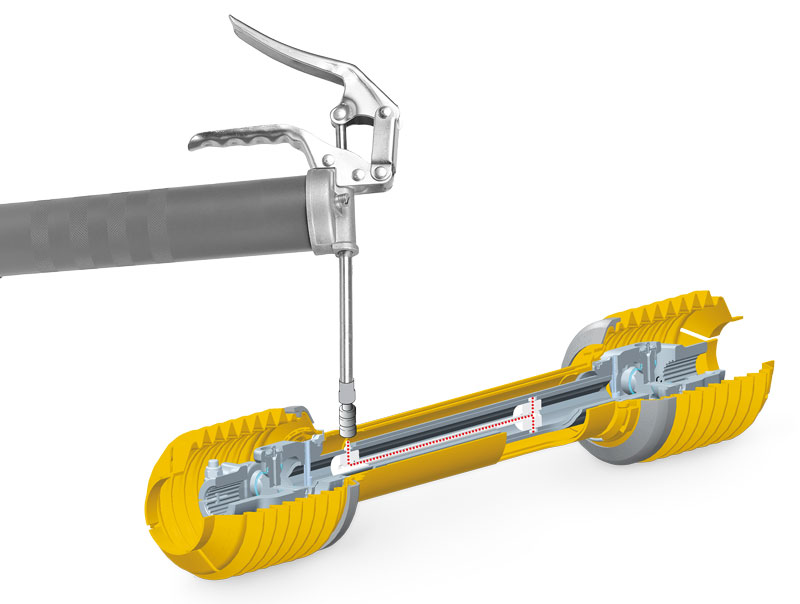

INNOVATIVE LUBRICATION SYSTEM FOR PROFILE TUBES – ease of maintenance and optimum lubricant distribution

Profile tube lubrication at a glance:

- Excellent accessibility of the lubrication points

- All lubrication points aligned in one plane

- Lubrication independent of length and position

- Even lubricant distribution via only a single lubricating grease nipple

The proven profile tubes are now available with the option of the new profile tube lubrication system. The distinguishing feature of this innovative system is the excellent accessibility of the lubrication points, with all lubrication points being aligned in one plane.

Lubrication takes place independently of length and position under all operating conditions. This not only helps prolong the service life and improve performance but also ensures simpler and maintenance-free handling of the drive shafts.

The new innovative lubrication system is available for the following pairs of profile tubes: 1b/2a – 1bGa/2aG – S4/S5 – S4H/S5 – S4LH/S5 – S4V/S5 – S4GA/S5 – S4LGA/S5 – S4VGA/S5.

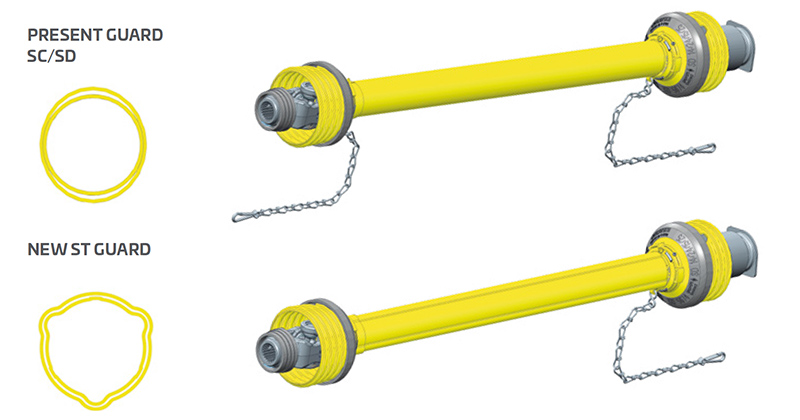

NEW ST GUARD FOR DRIVE SHAFT – Elimination of retaining chain

The "ST" profile tube at a glance:

- Profiled guard tube

- Easy handling

- Stability and low wear

- Connection between the inner and outer guard tubes is rotationally fixed, but telescopic

- Tractor-side retaining chain is dispensed with

- Possible consequential damage due to improper chain attachment no longer applies

- 100% compatibility with the present SD/SC guard of the same size

Walterscheid’s engineers have worked intensively on the individual components of the PTO drive shaft. This includes the guard tubes, for which the new profiled “ST” guard tube represents another such development. The “ST” guard tubes fixes rotationally the connection between the inner and outer guards. This means that one of the two previously common retaining chains can be dispensed with. An added benefit is that the drive shaft does not need any retaining chain when used in combination with the correct full guard on the implement side.

In this fundamental revision an important consideration was that the new ST drive shaft guard with the profiled guard tubes would be used with the proven guard components of the SC/SD series, such as guard cones and bearing rings, and that these combinations would fully comply with international safety regulations. This means that where the SC/SD guard tubes have been used to date, the new ST guard tubes can be used immediately.

Easy handling, reduced wear, stability, and compatibility with today’s SD/SC safety guards of the same size – excellent reasons to choose the new guard concept.

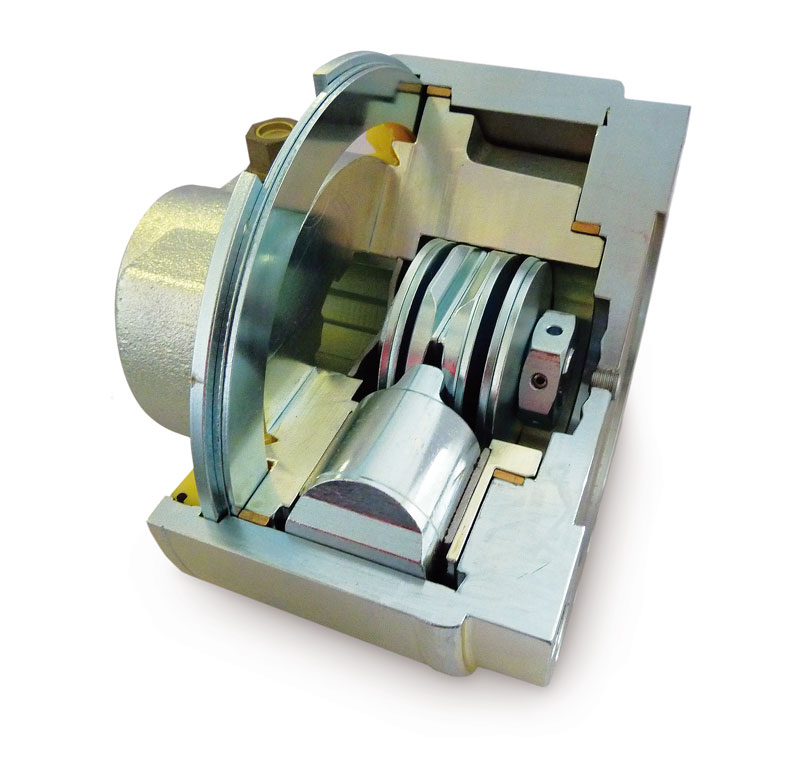

K68 / EK68 CAM-TYPE CUT-OUT CLUTCH – Prolonged service life, reduced maintenance and smooth running

The K68 / EK68 Cam-type cut-out clutch at a glance:

- Bearing-mounted hub

- Improved seal

- Optimised lubricant volume

- Smooth running even during and after the clutch has been engaged

- Significantly longer service life

- Greater reliability in use

- Reduced maintenance effort

Walterscheid’s decades of experience and expertise are also much in evidence in the development of the K68 / EK68 cam-type cut-out clutch. The new bearing concept that these clutches now use helps to achieve significantly quieter running.

Furthermore the lubricant volume has been increased and an improved seal installed. Thanks to these new features the K68 / EK68 experiences reduced wear of the cams, a lower risk of dirt contamination and a lower lubricant loss. This means a significant increase in service life and thus reliability.

Cam-type cut-out clutches serve a particular function in everyday operations: They provide effective protection for agricultural machinery with respect to overloads and they prevent expensive machine outages, downtimes and repairs.

The optimised K68 / EK68 cam-type cut-out clutch thus offers an ideal safety concept for use in modern agricultural machines which have to perform reliably.

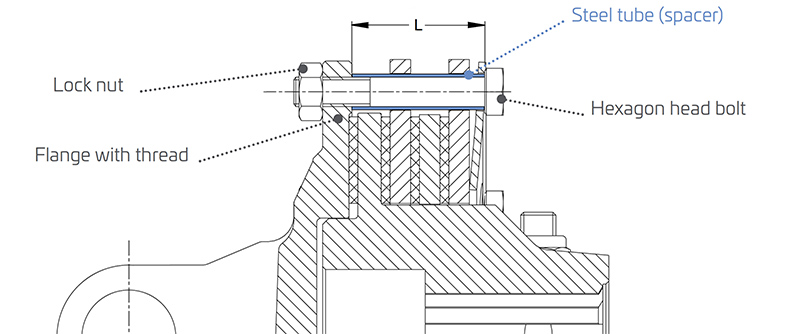

NEW K90TF FRICTION CLUTCH – for easy and quick mounting and maintenance of the drive shaft

The K90 and K90TF friction clutches at a glance:

- Easy and user-friendly ventilation

- Easy exchange of clutch linings

- Easily reproducible clutch settings

- Maximum service life through automatic compensation of friction lining wear

- Can be combined with overrunning clutch

- Highly consistent torque

The newly developed K90TF and K90/4TF friction clutches exhibit an impressively improved performance. But that’s not all: Walterscheid for the first time provides the opportunity to extend the use of the clutch lining. This makes life easier for the customer because the local agricultural machinery dealers can now also handle the maintenance and setting of the clutches. Previously, the only way was to have the clutch adjusted was either by the manufacturer or by specially authorised service partners, but now this can be done locally thus saving time and resources.

K90TF and K90/4TF friction clutch models are based on the proven K90 and K92 series. The driveline is effectively protected against high starting torques and any torque peaks which occur. A further advantage: The clutches are also extremely easy to maintain.

The spring characteristics of these clutches ensure automatic wear compensation, thus maximising service life. The linings can easily be replaced once they have reached the end of their useful life. Clutch setting are easily reproducible through well-defined spacers. K90TF and K90/4TF can be combined with an overrunning clutch, provide a consistent torque setting and overall excellent reliability.

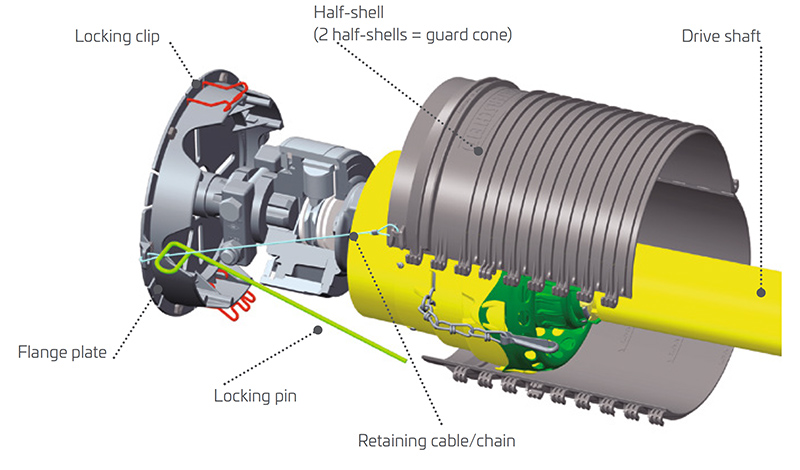

NEW PREMIUM GUARD CONE – for easy and quick mounting and maintenance of the drive shaft

The premium guard cone at a glance:

- Removable guard cone with two half shells which can be opened

- Guard cone can be mounted after connection of the drive shaft

- Easy mounting and dismantling

- Perfect accessibility

- Minimal installation space requirements

- Universal hole pattern for nearly all applications

- Sturdy and durable product from the use of high-quality materials

- Easy to retrofit existing machines

The new drive shaft guard concept also includes the new Walterscheid premium guard cones. These make mounting, dismantling and servicing drive shafts and clutches much easier. The implement-side premium guard cones are made of high-quality material and can be opened and removed in a few quick steps.

As compared to existing products, these new guard cones offer a whole range of advantages: They have 360-degree automatic locking and can be mounted after the connection of the drive shaft. Dismantling is also very convenient and user-friendly; the cone is pushed away from the gearbox flange plate by opening the locking clip.

The new premium guard cones have minimal requirements regarding the installation space, have a universal hole pattern for nearly all applications and are available in three lengths of 180mm, 240mm and 300mm; the inside diameter is 250mm in each case. There is no problem retrofitting existing machines with these new guard cones.

The ULTRA.PLUS System combines the best technologies and components of Walterscheid and is our innovative solution for maximum efficiency, service life, operational reliability and user-friendliness. Overall the ULTRA.PLUS system stands for the best drive shaft we have ever made.

More than 100 newly developed or re-engineered components are used for the Walterscheid ULTRA.PLUS drive shafts. The sum of many large and small development details ensures a much improved performance in all areas. This means that there is an optimised drive shaft for any application – and that doesn't only relate to the increasingly rigorous demands of agricultural machinery manufacturers.

With ULTRA.PLUS the end user also finds drive shafts that are geared perfectly to their specific needs.

Deutsch

Deutsch

English

English

Français

Français