Since connecting a manure tank to a tractor using Bluetooth is still not possible, various connectors will continue to accompany us into the age of Agriculture 4.0.

Mechanical connectors exist in many different systems. While bolt hitches were the “non plus ultra” just a few years ago, these have been largely replaced by the ball 80 system. Other frequently used connections include the hitch system, the Piton-Fix and the drawbar attachment. All of these systems are legitimate options and are more or less widespread in different European countries.

However, accidents happen occasionally due to connection devices failing from wear. It is therefore important, especially for repair shops, to know how to detect wear at an early stage using simple methods so you can ensure your customers’ safety.

In the upcoming articles on our website, we will use comparisons, contrasts and pro-and-con listings of various systems to create more awareness on the topic of connecting systems – so that you, and your clients, will always know which coupling to use and how to use it correctly in the future.

"We want to help optimise downtime and increase safety with our maintenance and wear tips",, says Maik Lehmann from Walterscheid. "Take a look to find out how you can detect wear at an early stage using simple methods and significantly increase safety!"

1. Most important maintenance tip

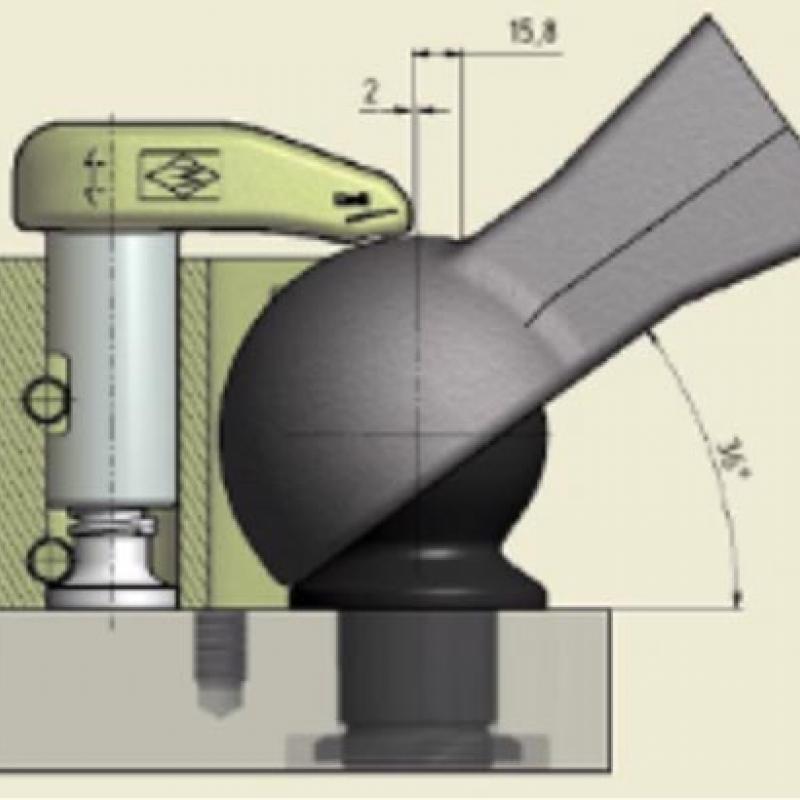

In the following article, we will explain the meaning and importance of setting the retainer correctly. For a safe and low-wear connection a trailer system with the ball 80 coupling, it is very important to set the retainer correctly to prevent unwanted play between the ball 80 and the calotte.

The optimal setting is 0.5 mm. In other words, a business card should just fit between the retainer and the calotte. It is important that a nearly form-fitting and play-free connection exists, as the force exerted by the supported load, especially by a negative supported load, transfers an enormous amount of stress to the retainer.

If the play is greater than 0.5 mm (manufacturer's specification), negative supported loads that occur can make deformation of the retainer more likely and cause increased wear.

Depending on the manufacturer, different versions of retainers are available on the market. The retainer can usually be adjusted to the optimal distance using a screw.

The retainer from Walterscheid® can be adjusted by hand relatively quickly without a tool.

- In addition to the calotte and the ball 80 coupling, the retainer itself should also be checked for wear. Deformations, bent retainers and torn bolt holes are all initial indications that the retainer is no longer in working condition. It should also be ensured that the contact surface, which according to manufacturer specifications is 0.5 mm from the calotte, is not already outside the permitted tolerance. To easily check the state of wear, the Walterscheid® retainer has a marking that indicates the maximum degree of wear. The wear on the top of the calotte can also be seen in this area.

- For an easy check, we at Walterscheid® offer a test calotte with which the retainer setting can be quickly and easily assessed.

Deutsch

Deutsch

English

English

Français

Français