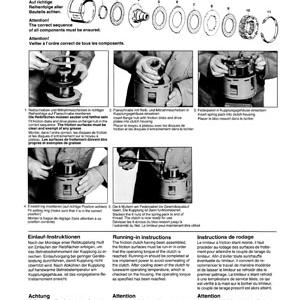

Friction- Overrunning clutch with spring package.

Friction clutches count among the torque-maintaining clutches and limit short-term torque peaks. Power transmission in the driveline is not interrupted. The clutch torque is dependent on the spring forces, the mean friction radius, the coefficient of friction and thenumber of friction linings. Friction clutches are particularly suitable for limiting loads during start-up processes, e.g. the acceleration of large masses. If the driveline is blocked, the entire energy to be transmitted is converted into heat. Overheating of the friction clutch can result in temporary reduction of the clutch torque or destroy the friction lining. The thermal loading capacity of friction clutches depends on the design type, the friction linings and the installation conditions. We exclusively use friction disks with a high thermal loading capacity.

Overrunning clutches transmit torques in one direction only. They are often used for reversing operations, in order to prevent loading by rotating masses. As a rule, pivoting, spring-loaded keys engage grooves. The flanks of these grooves are designed in such a way that driving by the locking keys is only possible in one direction. Preferred applications include rotary mowers and flywheel drives, often in the form of a combined friction and overrunning clutch.

Product advantages

No power transmission interruption

Covers peak loads for a short time

Torque is maintained

2 directions of rotation (clockwise and anticlockwise)

Adjustable

Suitable as a centrifugal coupling

The scope of delivery includes a complete friction- overrunning clutch PFBK96/4R.

Friction- Overrunning clutches should be checked regularly for play between the hub and the device journal. If there is too much play, the PTO shaft begins to „hit".

All components are designed specifically for the device and performance and it is not allowed to exchange for components other than those prescribed by Walterscheid. Damaged or missing parts can only replace with original Walterscheid parts and retrofit them in accordance with regulations and after consultation with Walterscheid.

The assignment, assembly and use of this model requires a detailed preliminary examination by qualified personnel. It is imperative to check the existing facilities and all of the machinery and equipment for their suitability for attachment. In particular, the characteristic values (e.g. vertical and pulling loads or torques) and the geometries (e.g. dimensions, screw hole patterns, free spaces) must be observed. Depending on the existing equipment of the machine, this can result in the use or purchase of additional components. The content of operating instructions must be observed.

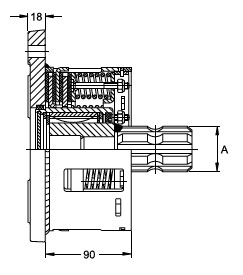

- Type

- PFBK96/4R

- Torque of clutch in daNm

- 135

- Set position of clutch

- II

- Pitch circle diameter

- 203

- Connecting PR hub

- KWP1 3/4-6V

- Holes/No of threads

- B12,5-3

- SNR.-Housing/E-Coupl

- 178091

- Torque tolerance class and dimension in %

- STANDARD

- Surface/Paint

- LACK.Yellow

- SNR-Housing/E-Coupl

- 124403

- Centering. AZ./IZ.

- AZ229H9

- Distance from drilling end

- 0

Deutsch

Deutsch

English

English

Français

Français