PowerDrive drive shaft without connection forks

Product advantages

PowerDrive universal drive shafts are specially designed for machines in continuous use and meet the highest requirements. Maintenance is usually carried out only once per season (every 250 hours - depending on application use). These long maintenance intervals are achieved through a number of technologies: The material of the protective bearings requires only minimal lubrication. The joints are equipped with special universal joint seals (multi-lip technology), whose shape and material prevent grease leakage or dust penetration. The profile tubes are optionally equipped with a grease nipple. These tubes are made of specially treated material that reduces sliding forces and minimizes wear on the profile tubes. Profile tube seals wipe off dirt and prevent grease loss. For easy handling of the PowerDrive drive shaft, the guard funnels can be easily unlocked and pushed back. The resulting free space makes it much easier to couple and uncouple the drive shafts and to maintain the joints and protective bearings. All PowerDrive joints are also equipped with bush bottom lubrication. Profiled, thick-walled protective tubes prevent the two protective halves from twisting relative to each other. The retaining chain on the tractor side therefore becomes superfluous. The risk of defects in the guard due to incorrect chain attachment is reduced. With the full guard version, supporting chains can be dispensed with altogether.

The scope of delivery includes a complete drive shaft size P700 with guard, retaining chain(s), operating and assembly instructions incl. declaration of conformity.

Connection forks are not included in the scope of delivery and must be purchased separately.

The standard design is suitable for the use of drive shafts with parallel axes. Depending on the application, it is recommended that a simple joint can be operated up to an angle of max. 25°. A constant angle during continuous operation of max. 15° should not be exceeded.

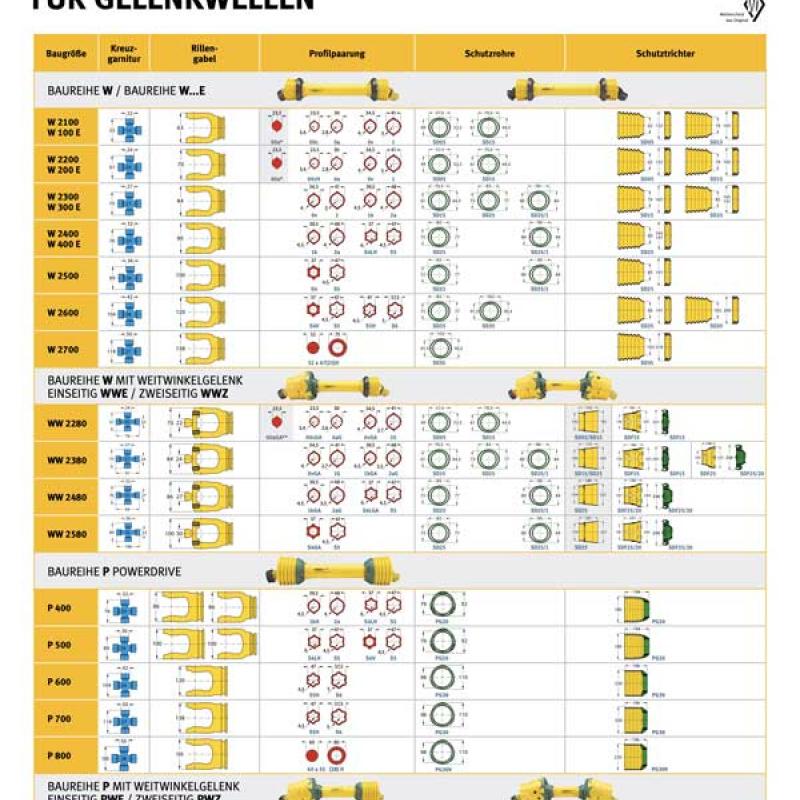

All components are designed specifically for the device and performance and it is not allowed to exchange for components other than those prescribed by Walterscheid. Damaged or missing parts can only replace with original Walterscheid parts and retrofit them in accordance with regulations and after consultation with Walterscheid.

The assignment, assembly and use of this model requires a detailed preliminary examination by qualified personnel. It is imperative to check the existing facilities and all of the machinery and equipment for their suitability for attachment. In particular, the characteristic values (e.g. vertical and pulling loads or torques) and the geometries (e.g. dimensions, screw hole patterns, free spaces) must be observed. Depending on the existing equipment of the machine, this can result in the use or purchase of additional components. The content of operating instructions must be observed.

- Type

- P

- Size

- 700

- Shaft length (Lz)

- 810

- Item no. attachment WH-A

- 139523

- Item no. attachment WH-I

- 139523

- Torque of clutch in daNm

- 0

- Rotation speed max. RPM

- 1000 UPM

- Cone type WH-I

- RP8

- Length of guard tube (outer)

- 480

- Cone Type WH-A

- RP8

- SNR cone WH-I

- 120038

- Nipple form / position I/A

- 6B 6B

- Length of guard tube (inner)

- 470

- Chain WH-A

- K

- Attachment type of profile

- AA

- SNR cone WH-A

- 120038

- Nipple on sliding profile

- PR-NIPP-6

- Protective colour

- Yellow

- Outer profile length

- 590

- Inner profile length

- 630

- Sliding profile seal

- PR-DICHTRING

- Cross seal

- P-DICHTUNG

- Abbreviation attachment WH-A

- ZK

- Abbreviation attachment WH-I

- ZK

- Profile tube - outer type

- S6

- Profile tube - inner type

- S5H

- Guard type

- PG30

Deutsch

Deutsch

English

English

Français

Français